Warehouse organization in Kastl

1986

At the beginning of the 1980s, the organization of inventories in production and warehouse halls was a predominantly manual matter. Computer technology was very rudimentary, if at all, only available in large companies, and so the entire warehousing was mainly based on experience, a sense of order and clearly defined work processes.

At that time, the camp system was a system of experience, discipline and a sense of craftsmanship. Written documentation and a clear spatial structure were the most important tools. Without modern technology, the warehouse relied heavily on the reliability and memory of its employees – an achievement that is often underestimated today.

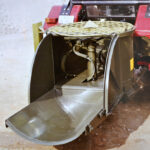

The production of the auger overload

In the 1980s, overload augers were increasingly used, which were mounted on agricultural tippers. They were used for the efficient and low-dust filling of seed containers on seed drills and other seed drills. The auger was hydraulically or mechanically driven and conveyed the seed directly from the tipper to the application hoppers at the rear of the tractor.

Thanks to its swivelling design, it enabled precise and time-saving filling without the need for bags or shovels. This not only made work easier, but also ensured even filling, helping to increase efficiency and efficiency.